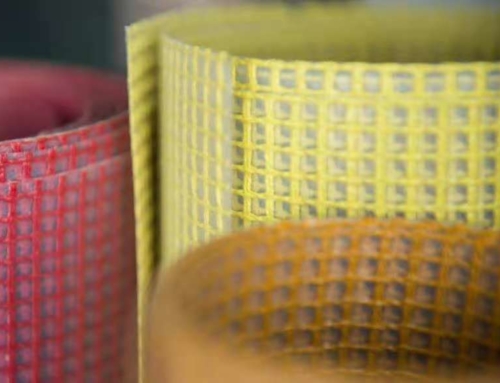

特氟龙涂层织物,塑料和聚合物加工用长效离型片

特氟龙涂层织物有或无粘合剂,在塑料和聚合物加工应用中用作离型片或传送带。从泡沫塑料(如聚氨酯泡沫塑料)的生产和固化,PVC门窗的焊接,塑料袋的制造,到橡胶和复合聚合物的固化和冷却。

永盛特氟龙涂层织物将是最佳解决方案,以保持一致的持久性能,减少设备停机时间,确保产品质量。

如何使用特氟龙涂层织物进行塑料和聚合物加工

固化或层压工艺要求高温高压,易脱模,特氟龙表面耐热260度,再加上玻璃纤维的高机械强度,使特氟龙涂层布可用作脱模片或脱模输送带,适用于各种塑料和聚合物加工行业。

在生产过程中,将特氟龙和塑料复合材料的复合材料表面的剥离时间降到最低。

不粘聚特氟龙输送带用于输送未固化的橡胶或聚合物,通过静压机、高温烘箱,最后输送到冷却部件。

特氟龙涂层布在塑料和聚合物加工中的应用

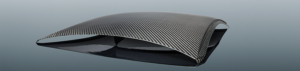

1) 汽车复合材料制造

特氟龙涂层玻纤布具有耐高温、耐磨损等特点,在汽车复合材料生产中用作离型片,具有重量轻、强度高的特点。如RMT、GMT、SMC(片状模塑料)。

汽车座椅、前端、车门托架、包裹架、扶手部件将使用聚四氟乙烯涂层织物(带或不带粘合剂)以实现出色的释放。

2) 碳纤维增强复合材料

碳纤维是一种新型的高模量、高强度纤维,碳含量在95%以上。碳纤维增强复合材料比钢具有更高的强度,更轻、更柔软。广泛应用于国防、军工和民用工业,如飞机工业、汽车工业等。

在碳纤维增强复合材料层压过程中,特氟龙涂层玻纤布将作为热压成型过程中的输送带和离型片。或者被切割成产品的形状(如碳纤维曲棍球),充当产品的脱模布。

该行业需要高强度特氟龙涂层玻纤布。

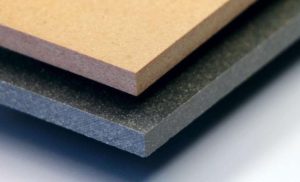

3) 泡沫生产和养护

特氟龙布能抵抗各种泡沫的高温固化,尤其是聚氨酯泡沫塑料,其固化温度最高。特氟龙涂层玻纤布的高拉伸强度和长寿命对产品质量和产量至关重要。

4) 聚合物复合材料的固化、铸造和塑性成型g

特氟龙涂层玻纤布有或无粘合剂可作为聚合物复合材料固化、浇铸和塑料成型的脱模片,因为特氟龙布耐磨、耐热、易脱模。

5) 塑料袋制造

塑料袋采用热焊封边,生产线高速封切。根据客户要求,该应用将使用特氟龙涂层玻纤布或自粘聚特氟龙涂层胶带,以防高温,并容易从焊接部件上松开塑料袋。

6) PVC门窗焊接释放装置

PVC门窗焊接要求在高温下连续工作,释放性能一致。特氟龙涂层织物具有优异的剥离表面,耐热性高达260°C,可防止熔化的PVC粘在焊接板上。

特氟龙高温布适用于各种焊接工艺,包括射频和微波系统。

Teflon fabric is a non stick release sheet or release belt for polymer or plastic curing or laminating.

As the composite material is developing fastly, the quality request for PTFE fabric will be higher, in order for meet the demand of machines with higher speed

My application is holding a sheet of carbon fiber down to a vacuum jig which has an array of small holes for the vacuum. the surface of the carbon fiber is too rough so the vacuum can’t hold it.

I hope that a layer of your PTFE fabric can help the vacuum to adhere

Hi Dr. Joleen Pater, YS9006P is a porous release sheet, and we think it might work for your application. It is worth trying anyway.

Our sales team will contact with you soon:)

Pleas advise how the teflon is applied to the sheeting. I have a particular project in mind that requires very high tensile strength fabric, with antifouling properties for the marine use. The idea of applying teflon is to act as antifouling, while at the same time as a vu resistance as product needs long life in outdoor environment. difficulty is will need to use Ultra high density polyethylene to create a sufficiently strong fabric and that this is not temperature stable… Also, should we find appropriate solution would need to produce lengths of 1000 m of treated fabric. How diverse is your company can you manage new product development. Please send all available details.